Shanghai Fante ElectroMechanical Equipment Manufacturing Co., Ltd. was established in 2000 and has a history of more than 20 years. The company is committed to becoming the best industry 4.0 system integration service provider, providing customers with excellent automated assembly lines, automated test benches and technical services. The company is now located in Shanghai Nanxiang High-tech Industrial Park, focusing on auto parts, advanced manufacturing automated assembly lines, automated assembly stations, tooling fixtures, automatic test and testing systems and other mechanical design, software development, system research and development, manufacturing, installation and debugging and other content, has rich experience. The company's business covers China, Asia, North America, Europe, etc., with more than 50 customers.

The design and development team members have more than 10 years of experience in the development of automation equipment and test systems, and have comprehensive development and design capabilities and engineering implementation experience. We also employ a team of consultants with more than 20 years of experience in the fields of mechanics, automation, optics, automatic control, etc., to provide systematic advice for the smooth implementation of each project.

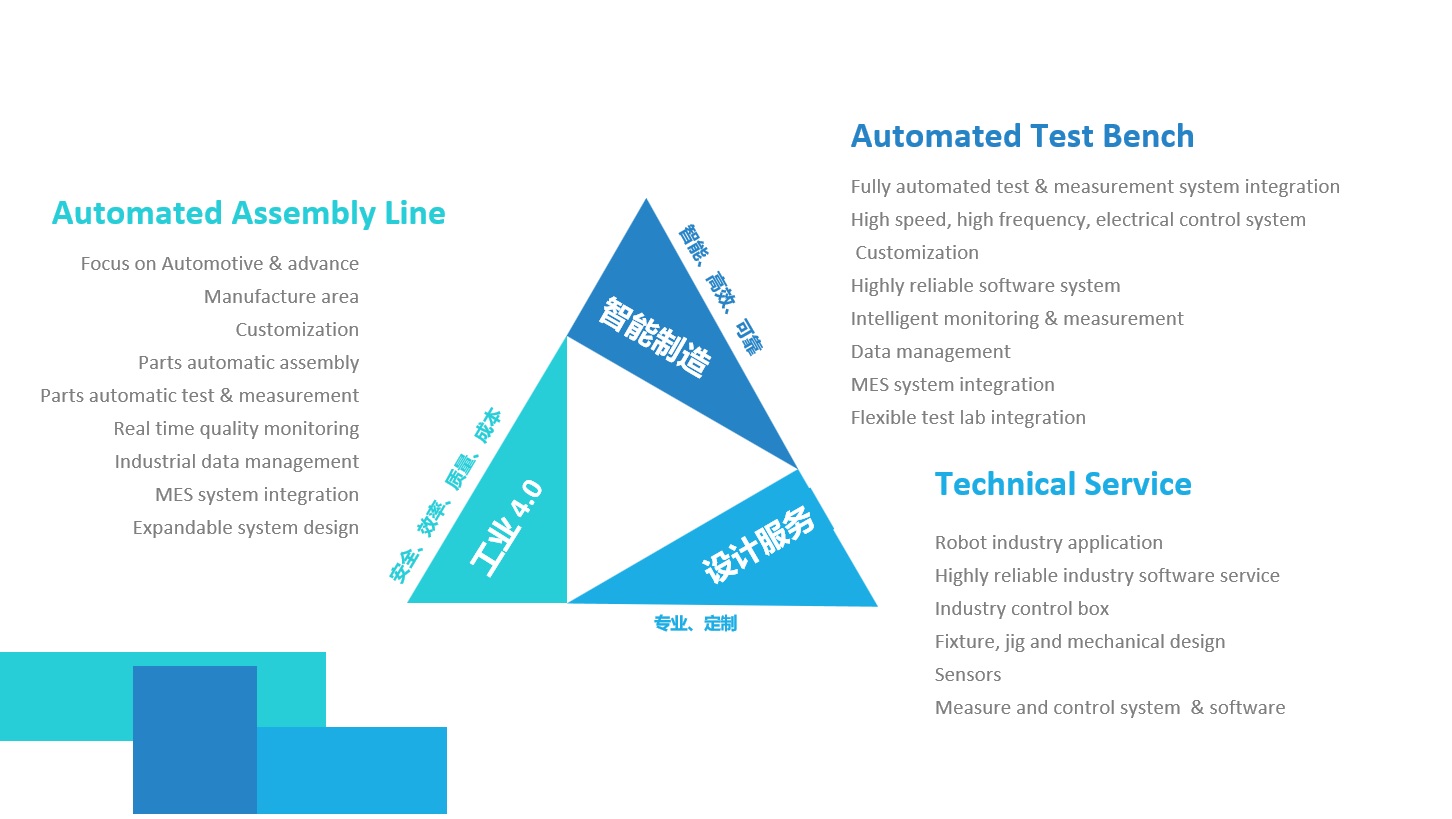

In the field of automated assembly lines, we provide customers with customized and cost-effective solutions. It has technical advantages in the fields of intelligent sensors and robot applications, helping customers improve product quality, improve production efficiency, reduce production costs and strengthen safety. In the field of automated test benches, we have rich experience in high-speed, high-frequency electronic control and hydraulic test systems, and provide customers with comprehensive automated test system solutions.

In the field of technical services, the company provides mechatronics design, robot application, industrial software development, high and low voltage electrical design, tooling fixtures and other services. We always work closely with the world's best suppliers, making extensive use of first-line brand components to ensure the quality of products from the source.

The tenet of Fante Mechanical and Electrical Service is "honest service, the pursuit of perfection", and grow together with customers. With the concept of full life cycle guarantee, through worry-free operation service, remote maintenance service, remote diagnosis and other means, to provide customers with spare parts, components, repair, maintenance, refurbishment, transformation and upgrade services. We believe that the needs of our customers are the driving force behind Fante's growth.

We have formed a series of equipment in the field of shock absorbers, covering passenger car shock absorbers, commercial vehicle shock absorbers, high-speed rail shock absorbers, and can provide complete automated assembly lines and automated test lines. Typical equipment includes shock absorber bottom valve pressure riveting machine, shock absorber piston groove machine, shock absorber piston valve dry adjustment machine, shock absorber cylinder connecting rod integrated machine, shock absorber clamp riveting machine, shock absorber refueling machine, shock absorber flanging machine, shock absorber support ring pressure riveting machine, shock absorber inflator, shock absorber dynamometer (electric, hydraulic), shock absorber high-frequency fatigue test bench, air shock absorber air bag assembly, shock absorber repair line, etc. We have formed a series of equipment in the field of automotive brake hoses. Typical equipment includes semi-automatic and fully automatic production lines such as brake oil pipe weaving machine, automatic riveting of brake oil pipe, automatic pressure test of brake oil pipe, automatic detection of brake oil pipe, etc.

Shanghai Fante M&E Equipment Co., Ltd. sincerely looks forward to working with you to cooperate with you for common development and create brilliance together.

Customized industrial-grade mechanical structure design to ensure high reliability, stability and high precision

Through PLC, industrial computer and other advanced control systems, combined with project requirements, the framework mode is used for industrial software development

Excellent industrial project management team, through strict process management, timely and efficient project delivery

Industrial robot application design, development, implementation capabilities, support major mainstream brands SCARA and 6-axis robot projects

Provide intelligent vision system design, development and application, combined with a variety of mainstream high-performance intelligent sensors, to achieve comprehensive intelligent control

Provide customers with customized industrial digital systems, at the SCADA level, to achieve efficient equipment and process data collection, storage, on-site Kanban display, electronic work orders and other functions.

Shock absorber test equipment (dynamometer), suitable for passenger cars, trucks, railway various types of shock absorbers. Including monocular, binocular, transverse, vertical, passive, semi-active (CDC, magnetorheology), active and other types

shock absorber test equipment, the drive form includes electromechanical, electric servo, electro-hydraulic servo, linear motor drive, etc

applications, including performance laboratory, fatigue endurance test, production line final inspection, rework test, vehicle field test, etc

Main performance indicators:

Maximum driving force: single-acting 25,000N; Fatigue durability 100,000N/4 sticks

Minimum speed: 0.001m/s can be customized as needed

Maximum speed: electric servo 1.5m/s; Hydraulic servo 2.5m/s; Linear motor 4m/s can be customized on request

Signal type: sinusoidal, square, triangle or arbitrary

Force sensor accuracy: 0.01%, 0.02%, 0.5%, 1% Optional

Displacement sensor accuracy: 0.005mm, 0.01mm

Test stroke: 2mm, 4mm, 12.5mm, 25mm, 50mm, 75mm, 100mm, 150mm can be customized on demand

Intelligent bench, suitable for passenger car human-machine structure evaluation, human-computer interaction evaluation, intelligent cockpit development verification, static or dynamic simulation cockpit, design exhibition vehicles, etc. As an intelligent bench, including chassis module, seat module, IP module, windshield module,

It consists of instrument cluster module, steering module, throttle brake module, center armrest module, ABCD column module, control cabinet, remote control and communication module.

Each module is controlled and driven by a servo motor with an absolute encoder and is capable of recording and storing positions. Through the host computer control program, the setting information of a variety of models stored can be called to achieve one-key adjustment, so as to quickly switch and greatly speed up the development process

Main component performance indicators:

Chassis: support single-seat, two-seat, 4-seater, 5-seater, 6-seater, 7-seater and other types; The chassis height is electrically adjustable

Seat module: first row electric lifting, front and rear, left and right adjustment; Second and third row electric lifting, front and rear, left and right, rotation and pitch. Can be customized upon request

IP module: electric up and down, moving back and forth; Left and right stretches can be customized

Windshield module: electric flip

Dashboard module: electric telescopic, left and right movement; Manual rotation, flipping; Adapt to screen size 7-17 inch screen; Customizable screen adaptation bracket

Steering module: the steering wheel can be replaced, and the steering wheel communication is supported; The steering wheel tube column is electrically telescopic, pitched, left and right movement; The steering wheel turns electrodynamic feedback, and the feedback force can be adjusted and set;

Throttle brake module: throttle and brake pedal electric pitch, left and right movement; Accelerator pedal force feedback; Brake pedal electrodynamic feedback, feedback force can be adjusted and set

Control accuracy: 1mm or 0.5 degrees; Can be customized upon request

Communication mode: support Ethernet, CAN bus, Wifi, etc.; Can be customized upon request